Application area

Usage :Suitable for Aluminium Extrusion Die, and Aluminium Copper forging Die.

Characteristic :H13 has high hard resistance and hardness.

Similar steel grade

|

标准 |

GB |

JIS |

ASTM |

ISO |

DIN |

|

钢号 |

4Cr5MoSiV1 |

SKD 61 |

H13 |

140CrMoV5 |

1.2344 |

Chemical Composition :(%)

|

C |

W |

Mo |

Cr |

V |

Mn |

Si |

P |

S |

|

0.35-0.42 |

|

1.20-1.50 |

4.80-5.50 |

0.85-1.15 |

0.25-0.50 |

0.80-1.20 |

≤0.030 |

≤0.030 |

Hardness : ≤HB235

UT standard :

SEP1921,(DEC.84)E/e

Delivery status:

In annealed condition.

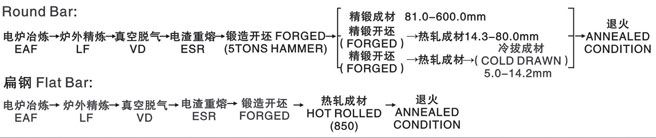

Size :

Hot rolled flat bar

Thickness:10mm-100mm

Width:200-710mm

Round bar

Diametar:5-600mm

Heat Treatment condition :

Quenching temperature:1020-1050℃

Cooling Medium:air-cooling

Tempering temperature:560-580℃,by two times;

Tempering Hardness:47-48HRC

|

Tempering ℃ |

100℃ |

200℃ |

300℃ |

400℃ |

500℃ |

550℃ |

600℃ |

650℃ |

700℃ |

|

HRC |

HRC63 |

HRC52 |

HRC52 |

HRC54 |

HRC56 |

HRC54 |

HRC50 |

HRC42 |

HRC32 |

Today our TG can produce & supple other different grade steel as following:

|

Grade |

GB |

DIN |

AISI |

Form of Supply |

|

钢号 |

中国牌号 |

|

美国牌号 |

供应类型 |

|

1.2080 |

Cr12 |

X210Cr12 |

D3 |

圆钢/扁钢(Round Bar/Flat Bar) |

|

1.2842 |

9Mn2V |

90MnCrV8 |

02 |

|

|

1.2510 |

9CrWMn |

100MnCrW4 |

01 |

圆钢/扁钢(Round Bar/Flat Bar) |

|

1.2363 |

Cr5Mo1V |

X100CrMo5 |

A2 |

圆钢/扁钢(Round Bar/Flat Bar) |

|

1.2343 |

4Cr5MoSiV1 |

X38CrMoV5-1 |

H11 |

圆钢(Round Bar) |

|

1.2367 |

|

X38CrMoV5-3 |

|

圆钢(Round Bar) |

|

1.2083 |

|

X42Cr13 |

420 |

扁钢(Flat Bar) |

|

1.2085 |

|

X33CrS16 |

|

扁钢(Flat Bar) |

|

1.2311 |

|

40CrMnMo7 |

|

扁钢(Flat Bar) |

|

1.2738 |

|

40CrMnNiMo8-6-1 |

|

扁钢(Flat Bar) |

|

1.2714 |

|

56NiCrMoV7 |

L6 |

圆钢(Round Bar) |

|

1.2767 |

|

X45NiCrMo4 |

|

圆钢(Round Bar) |

|

1.2357 |

|

50CrMoV13-14 |

S7 |

圆钢(Round Bar) |

Notice:If you have any question for the supplying sizes range of above mentioned,different grade steel,please contact with our sales peoples!Tks! And our TG can develop some other new grade steel of High Alloy according Customer's detail inquiry.

钢材硬度对照参考表

Hardness Comparison Table

|

抗拉强度 |

维氏硬度 |

布氏硬度 |

洛氏硬度 |

抗拉强度 |

维氏硬度 |

布氏硬度 |

洛氏硬度 |

|

Rm |

HV |

HB |

HRC |

Rm |

HV |

HB |

HRC |

|

N/mm2 |

|

|

|

N/mm2 |

|

|

|

|

255 |

80 |

76 |

- |

660 |

205 |

195 |

- |

|

270 |

85 |

80.7 |

- |

675 |

210 |

199 |

- |

|

285 |

90 |

85.2 |

- |

690 |

215 |

204 |

- |

|

305 |

95 |

90.2 |

- |

705 |

220 |

209 |

- |

|

320 |

100 |

95 |

- |

720 |

225 |

214 |

- |

|

335 |

105 |

99.8 |

- |

740 |

230 |

219 |

- |

|

350 |

110 |

105 |

- |

755 |

235 |

223 |

- |

|

370 |

115 |

109 |

- |

770 |

240 |

228 |

20.3 |

|

380 |

120 |

114 |

- |

785 |

245 |

233 |

21.3 |

|

400 |

125 |

119 |

- |

800 |

250 |

238 |

22.2 |

|

415 |

130 |

124 |

- |

820 |

255 |

242 |

23.1 |

|

430 |

135 |

128 |

- |

835 |

260 |

247 |

24 |

|

450 |

140 |

133 |

- |

850 |

265 |

252 |

24.8 |

|

465 |

145 |

138 |

- |

865 |

270 |

257 |

25.6 |

|

480 |

150 |

143 |

- |

880 |

275 |

261 |

26.4 |

|

490 |

155 |

147 |

- |

900 |

280 |

266 |

27.1 |

|

510 |

160 |

152 |

- |

915 |

285 |

271 |

27.8 |

|

530 |

165 |

156 |

- |

930 |

290 |

276 |

28.5 |

|

545 |

170 |

162 |

- |

950 |

295 |

280 |

29.2 |

|

560 |

175 |

166 |

- |

965 |

300 |

285 |

29.8 |

|

575 |

180 |

171 |

- |

995 |

310 |

295 |

31 |

|

595 |

185 |

176 |

- |

1030 |

320 |

304 |

32.2 |

|

610 |

190 |

181 |

- |

1060 |

330 |

314 |

33.3 |

|

625 |

195 |

185 |

- |

1095 |

340 |

323 |

34.4 |

|

640 |

200 |

190 |

- |

1125 |

350 |

333 |

35.5 |

|

1115 |

360 |

333 |

36.6 |

2030 |

610 |

(570) |

55.7 |

|

1190 |

370 |

342 |

37.7 |

2070 |

620 |

(580) |

56.3 |

|

1220 |

380 |

352 |

38.8 |

2105 |

630 |

(589) |

56.8 |

|

1255 |

390 |

361 |

39.8 |

2145 |

640 |

(599) |

57.3 |

|

1290 |

400 |

371 |

40.8 |

2180 |

650 |

(608) |

57.8 |

|

1320 |

410 |

380 |

41.8 |

|

660 |

(618) |

58.3 |

|

1350 |

420 |

390 |

42.7 |

|

670 |

|

58.8 |

|

1385 |

430 |

399 |

43.6 |

|

680 |

|

59.2 |

|

1420 |

440 |

409 |

44.5 |

|

690 |

|

59.7 |

|

1455 |

450 |

418 |

45.3 |

|

700 |

|

60.1 |

|

1485 |

460 |

428 |

46.1 |

|

720 |

|

61 |

|

1520 |

470 |

437 |

46.9 |

|

740 |

|

61.8 |

|

1555 |

480 |

447 |

47.7 |

|

760 |

|

62.5 |

|

1595 |

490 |

(456) |

48.4 |

|

780 |

|

63.3 |

|

1630 |

500 |

(466) |

49.1 |

|

800 |

|

64 |

|

1665 |

510 |

(475) |

49.8 |

|

820 |

|

64.7 |

|

1700 |

520 |

(485) |

50.5 |

|

840 |

|

65.3 |

|

1740 |

530 |

(494) |

51.1 |

|

860 |

|

65.9 |

|

1775 |

540 |

(504) |

51.7 |

|

880 |

|

66.4 |

|

1810 |

550 |

(513) |

52.3 |

|

900 |

|

67 |

|

1845 |

560 |

(523) |

53 |

|

920 |

|

67.5 |

|

1880 |

570 |

(532) |

53.6 |

|

940 |

|

68 |

|

1920 |

580 |

(542) |

54.1 |

|

|

|

|

|

1955 |

590 |

(551) |

54.7 |

|

|

|

|

|

1995 |

600 |

(561) |

55.2 |

|

|

|

|

Production engineering

Copyright:Jiangsu Tiangong Tools Co., Ltd. Address:Houxiang,Danbei Town,Danyang City,Jiangsu Province,China

《The People's Republic of China Telecommunications and information services Business license》Number: 苏ICP备06046378号-1