Usage :Applied in thickness no less than 2mm punch mould,all kind of small mould for shearing and cutter together with screw rolled of slappered mould as well as some other forming mould like rulers.

Characteristic :Characteristic: E.S.R. materials, high compression stregth and fine robustness. The spheroical annealed make it easily processed by shearing and cutting ith no crake while processing.

Similar steel grade

|

标准 |

GB |

JIS |

ASTM |

ISO |

DIN |

|

钢号 |

Cr12mO1V1 |

SKD 11 |

D2 |

160CrMoV12 |

1.2379 |

Chemical Composition :(%)

|

C |

W |

Mo |

Cr |

V |

Mn |

Si |

P |

S |

|

1.45-1.60 |

|

0.70-1.00 |

11.00-13.00 |

0.70-1.00 |

0.20-0.60 |

0.10-0.60 |

≤0.030 |

≤0.030 |

Hardness : ≤255HB

UT standard :

SEP1921,(DEC.84)E/e

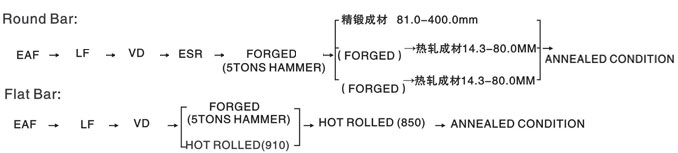

Delivery status:

As Hot rolled & forged,delivery condition:annealed

Size :

Flat Bar

Thickness:12mm-80mm

Width:200mm-710mm

Round Bar

2.1mm-400mm

Heat Treatment condition :

Quenching temperature:1000-1040℃

Cooling Medium: oil-cooling or air-cooling

Tempering temperature:180-200℃,by two times;

Tempering Hardness:63.0HRC

Heat Treatment condition:

Quenching temperature:1060-1080℃

Cooling Medium: oil-cooling or air-cooling

Tempering temperature:500-540℃,by two times;

Tempering Hardness:59.0-61.0HRC

Today our TG can produce & supple other different grade steel as following:

|

Grade |

GB |

DIN |

AISI |

Form of Supply |

|

钢号 |

中国牌号 |

|

美国牌号 |

供应类型 |

|

1.2080 |

Cr12 |

X210Cr12 |

D3 |

圆钢/扁钢(Round Bar/Flat Bar) |

|

1.2842 |

9Mn2V |

90MnCrV8 |

02 |

|

|

1.2510 |

9CrWMn |

100MnCrW4 |

01 |

圆钢/扁钢(Round Bar/Flat Bar) |

|

1.2363 |

Cr5Mo1V |

X100CrMo5 |

A2 |

圆钢/扁钢(Round Bar/Flat Bar) |

|

1.2343 |

4Cr5MoSiV1 |

X38CrMoV5-1 |

H11 |

圆钢(Round Bar) |

|

1.2367 |

|

X38CrMoV5-3 |

|

圆钢(Round Bar) |

|

1.2083 |

|

X42Cr13 |

420 |

扁钢(Flat Bar) |

|

1.2085 |

|

X33CrS16 |

|

扁钢(Flat Bar) |

|

1.2311 |

|

40CrMnMo7 |

|

扁钢(Flat Bar) |

|

1.2738 |

|

40CrMnNiMo8-6-1 |

|

扁钢(Flat Bar) |

|

1.2714 |

|

56NiCrMoV7 |

L6 |

圆钢(Round Bar) |

|

1.2767 |

|

X45NiCrMo4 |

|

圆钢(Round Bar) |

|

1.2357 |

|

50CrMoV13-14 |

S7 |

圆钢(Round Bar) |

Notice:If you have any question for the supplying sizes range of above mentioned,different grade steel,please contact with our sales peoples!Tks! And our TG can develop some other new grade steel of High Alloy according Customer's detail inquiry.

钢材硬度对照参考表

Hardness Comparison Table

|

抗拉强度 |

维氏硬度 |

布氏硬度 |

洛氏硬度 |

抗拉强度 |

维氏硬度 |

布氏硬度 |

洛氏硬度 |

|

Rm |

HV |

HB |

HRC |

Rm |

HV |

HB |

HRC |

|

N/mm2 |

|

|

|

N/mm2 |

|

|

|

|

255 |

80 |

76 |

- |

660 |

205 |

195 |

- |

|

270 |

85 |

80.7 |

- |

675 |

210 |

199 |

- |

|

285 |

90 |

85.2 |

- |

690 |

215 |

204 |

- |

|

305 |

95 |

90.2 |

- |

705 |

220 |

209 |

- |

|

320 |

100 |

95 |

- |

720 |

225 |

214 |

- |

|

335 |

105 |

99.8 |

- |

740 |

230 |

219 |

- |

|

350 |

110 |

105 |

- |

755 |

235 |

223 |

- |

|

370 |

115 |

109 |

- |

770 |

240 |

228 |

20.3 |

|

380 |

120 |

114 |

- |

785 |

245 |

233 |

21.3 |

|

400 |

125 |

119 |

- |

800 |

250 |

238 |

22.2 |

|

415 |

130 |

124 |

- |

820 |

255 |

242 |

23.1 |

|

430 |

135 |

128 |

- |

835 |

260 |

247 |

24 |

|

450 |

140 |

133 |

- |

850 |

265 |

252 |

24.8 |

|

465 |

145 |

138 |

- |

865 |

270 |

257 |

25.6 |

|

480 |

150 |

143 |

- |

880 |

275 |

261 |

26.4 |

|

490 |

155 |

147 |

- |

900 |

280 |

266 |

27.1 |

|

510 |

160 |

152 |

- |

915 |

285 |

271 |

27.8 |

|

530 |

165 |

156 |

- |

930 |

290 |

276 |

28.5 |

|

545 |

170 |

162 |

- |

950 |

295 |

280 |

29.2 |

|

560 |

175 |

166 |

- |

965 |

300 |

285 |

29.8 |

|

575 |

180 |

171 |

- |

995 |

310 |

295 |

31 |

|

595 |

185 |

176 |

- |

1030 |

320 |

304 |

32.2 |

|

610 |

190 |

181 |

- |

1060 |

330 |

314 |

33.3 |

|

625 |

195 |

185 |

- |

1095 |

340 |

323 |

34.4 |

|

640 |

200 |

190 |

- |

1125 |

350 |

333 |

35.5 |

|

1115 |

360 |

333 |

36.6 |

2030 |

610 |

(570) |

55.7 |

|

1190 |

370 |

342 |

37.7 |

2070 |

620 |

(580) |

56.3 |

|

1220 |

380 |

352 |

38.8 |

2105 |

630 |

(589) |

56.8 |

|

1255 |

390 |

361 |

39.8 |

2145 |

640 |

(599) |

57.3 |

|

1290 |

400 |

371 |

40.8 |

2180 |

650 |

(608) |

57.8 |

|

1320 |

410 |

380 |

41.8 |

|

660 |

(618) |

58.3 |

|

1350 |

420 |

390 |

42.7 |

|

670 |

|

58.8 |

|

1385 |

430 |

399 |

43.6 |

|

680 |

|

59.2 |

|

1420 |

440 |

409 |

44.5 |

|

690 |

|

59.7 |

|

1455 |

450 |

418 |

45.3 |

|

700 |

|

60.1 |

|

1485 |

460 |

428 |

46.1 |

|

720 |

|

61 |

|

1520 |

470 |

437 |

46.9 |

|

740 |

|

61.8 |

|

1555 |

480 |

447 |

47.7 |

|

760 |

|

62.5 |

|

1595 |

490 |

(456) |

48.4 |

|

780 |

|

63.3 |

|

1630 |

500 |

(466) |

49.1 |

|

800 |

|

64 |

|

1665 |

510 |

(475) |

49.8 |

|

820 |

|

64.7 |

|

1700 |

520 |

(485) |

50.5 |

|

840 |

|

65.3 |

|

1740 |

530 |

(494) |

51.1 |

|

860 |

|

65.9 |

|

1775 |

540 |

(504) |

51.7 |

|

880 |

|

66.4 |

|

1810 |

550 |

(513) |

52.3 |

|

900 |

|

67 |

|

1845 |

560 |

(523) |

53 |

|

920 |

|

67.5 |

|

1880 |

570 |

(532) |

53.6 |

|

940 |

|

68 |

|

1920 |

580 |

(542) |

54.1 |

|

|

|

|

|

1955 |

590 |

(551) |

54.7 |

|

|

|

|

|

1995 |

600 |

(561) |

55.2 |

|

|

|

|

Production engineering

Copyright:Jiangsu Tiangong Tools Co., Ltd. Address:Houxiang,Danbei Town,Danyang City,Jiangsu Province,China

《The People's Republic of China Telecommunications and information services Business license》Number: 苏ICP备06046378号-1